,

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Machining

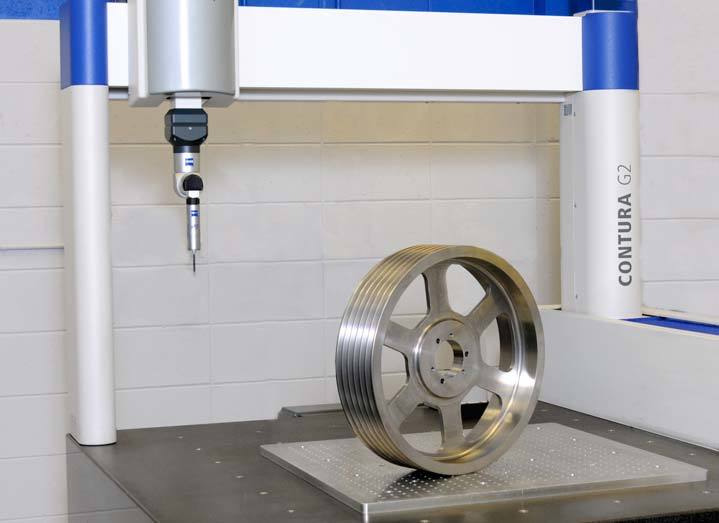

Precision Machining

Marini Manufacturing's world class equipment is ready to meet the most demanding requirements for today's machining needs. Critical features and positional relationship tolerances are assured through the selection of proper equipment and tooling. We have extensive experience machining the full range of materials (ductile iron, steel, ADI, aluminum and other exotics), through processes including:

- Horizontal Machining (400mm to 800mm)

- Vertical Machining (400mm to 630mm)

- Lathes (2-Axis, Live Tool, Horizontal and Vertical to 850mm)

Assembly

Marini Manufacturing is capable of providing sub-assembly when needed. By utilizing cycle time, we optimize cost. We are also capable of torque, pressure and functional tests per customer requirements.

Engineering

With engineering resources on staff, we are able to fully optimize fixture and tooling concepts for specific customer needs. That optimization allows for shorter lead times and faster product launch.

Fixture and Tooling

Our tool and fixture expertise provides innovation, flexibility, and rapid response during key prototype and production stages. We also provide continuous cast iron services.

Continuous Cast Iron - Machining Solutions

Need a fast turnaround on prototype or production parts, and there's no time to wait for castings? Is casting porosity costing you money? Need service parts machined, and you can't locate the patterns or want to sink more money into the repair of the tooling for such a limited run?

Let our expertise in machining continuous cast iron bar be put to work for you!

Benefits

- Lower total parts cost

- Improved material availability

- High material quality and consistency

Continuous cast iron is the #1 steel alternative on the market and for good reason. The continuous casting process makes possible the production of bars with fine-grained as-cast structure, and this allows for free machining, wear resistance, and good mechanical properties.

The continuous cast process ensures the iron solidifies at a uniformed rate making the iron more durable and reliable than other alternatives. Continuous cast iron uses less scrap than alternatives leading to a sound, strong product.

Applications

- Pulleys

- Bearing

- Housings

- Pistons

- Manifolds

- Gears

- Prototypes

- Service and obsolete parts

Shapes and Sizes

With rounds, tube, squares, and rectangle stock available in a wide variety of sizes, continuous cast iron offers across the board superior machinability.

Summary

With a wide variety of continuous cast production and service machined part programs, our dedicated team stands ready to answer your questions and get a quote to you ASAP. Contact us

today!

VISIT US

,

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

CONTACT US

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Hi. Do you need any help?

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.

Share On: